History of vaz 2104 last year of release. Postmodernism supplanted the classics

photo VAZ-2104 "Universal"

VAZ 2104- Soviet a car with a station wagon body type, developed at the VAZ plant. Serially produced from 1984 to 2012. The model was developed as a replacement for the outdated station wagon 2102. For some time, 2102 and 2104 were produced in parallel at the plant. When creating a new model at the plant, they followed the path of the lowest costs and used the VAZ 2105 as the base model. All parts were subjected to maximum unification. To give rigidity, stampings appeared on the roof of the new model. In contrast to the 2102 model, a heated rear window was installed on the "four" in the basic configuration. From the mid-1990s, a rear wiper will be fitted as standard. The base model received a saloon from the model 2105. The station wagon's carrying capacity was 455 kg, which is almost double the maximum carrying capacity of 2102. The model inherited the tailgate design from its predecessor. Its edge coincided with the floor level, which facilitated the loading and unloading of baggage. The rear seat folded down to form a huge loading bay.

photo trunk VAZ-2104

Modifications of the VAZ-2104

The following models were produced: - 21041, 21043 and 21043-07, differing in engines of 1.2 liters, 1.5 liters and a "seven" saloon, respectively. In 1994, the VAZ-2104 with a 1.3-liter engine was discontinued. Today, the base model is the VAZ 21043 with a 1.5-liter engine and a five-speed mechanical box gears, which makes the AW car VAZ 21043 more dynamic and pleasant to drive. Not so long ago, a modification of the VAZ-21045 appeared with an atmospheric (naturally aspirated) diesel engine produced by Barnaultransmash, with a volume of 1.52 liters.

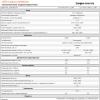

| VAZ-2104 | VAZ-2105 engine, 1.3 liters, carburetor, with 4-gearbox), base model |

| VAZ-21041 | VAZ-2101 engine, 1.2 liters, carburetor with 4-gearbox. Not serially produced. |

| VAZ-21042 | VAZ-2103 engine, 1.5 liters, right hand drive |

| VAZ-21043 | VAZ-2103 engine, 1.5 liters, carburetor with 4- or 5-gearbox, in versions with electrical equipment and interior from VAZ-2107 |

| VAZ-21044 | VAZ-2107 engine, 1.7 liters, single injection, 5-gearbox, export model |

| VAZ-21045 | VAZ-2107 engine, 1.8 liters, single injection, 5-gearbox, export model. Not serially produced. |

| VAZ-21045D | VAZ-341 engine, 1.5 liters, diesel, 5-gearbox |

| VAZ-21047 | VAZ-2103 engine, 1.5 liters, carburetor, 5-gearbox, improved version with interior from VAZ-2107. Export modifications were equipped with a radiator grill from the VAZ-2107. |

| VAZ-21048 | VAZ-343 engine, 1.8 liters, diesel, 5-gearbox |

| VAZ-21041i | engine VAZ-21067 1.6 liter injector, 5-gearbox, interior and electrical equipment VAZ-2107 |

| Export names VAZ-2104 | |

| Lada riva | UK and mainland European countries |

| Lada nova | Germany and mainland European countries |

| Lada 1500 or Lada Signet | Canada |

| Lada laika | Brazil |

photo VAZ-2104 rear view

photo of VAZ-2104

Interior design and controls

Generally design of the VAZ-2104 model, like all classic models, austere. But the interior of the car, depending on your desire, can be different. A more economical option involves a standard panel with the minimum required set of switches and instrumentation, upholstery and seats with standard artificial leather head restraints, rubber floor mats. If you want more comfort, then you are offered an improved interior, an original wheel and a dashboard with an additional center console, which has an expanded set of function keys and control equipment. The improved interior includes seats upholstered in brushed jersey (front with a high backrest), doors with one-piece moldings, and brushed floor mats. This variant of the "four" will allow you to feel comfortable even on a long trip.

photo salon VAZ-2104

The VAZ-2104 engine and its features

Engine 2104-1000260 can be used for installation on cars VAZ 2103, 2104, 2106, 21053, 2107.

Initially, the VAZ 2104 engine was produced only in a carburetor version. Later it was modified to use the fuel injection system and received the designation VAZ 2104-21.

The VAZ 2104 engine is based on previous model- VAZ 2103. The design used: a cylinder block, a connecting rod-piston group, a timing drive and a crankshaft from the 2103 engine.

photo engine VAZ-2104

The cylinder block is from the VAZ 2103 engine. The cylinder diameter is 76.00 mm. The accepted overhaul sizes are 76.40 and 76.80. The engine is fitted with a 2103 crankshaft or a 21213 interchangeable shaft.

To ensure the operation of the injection system, it was required to install units and parts from other engines, which were originally developed for an injection fuel supply scheme. A new camshaft drive cover is used, on which there is a place for installing a sensor that monitors the position of the crankshaft. It took the installation of a cylinder head 2104-1003015, an original design, with enlarged areas for the intake manifold. The design of the head provides for the installation of nozzles. The camshaft, valves and springs correspond to those installed on the VAZ 2103 engine. Installation of hydraulic supports for valve levers is not provided.

The timing is driven by a double-row sleeve-roller chain 2103-1006040. The chain tensioning mechanism is mechanical, similar to the device on the VAZ 2103 engine.

A pulley with a damper and a master disk 21214-1005058-11 is installed on the crankshaft. To drive the generator, a belt 2107-1308020 (length - 944mm) is used. The injector modification 2104 has an original power system. The system includes an electric fuel pump with a fuel gauge sensor, fuel lines, a fuel filter, a fuel rail with injectors, an air filter, air supply hoses, a throttle valve and a fuel vapor recovery system. To clean the air entering the engine, a model 2112 air filter is provided. A model 2104 or model 2123-1008027 air receiver is installed with the intake manifold. To adjust the volume of incoming air, a throttle pipe 2112 is installed.

The electric fuel pump module 21073-1139009 is installed in the tank and provides fuel supply to the fuel rail and injectors. Used original fuel rail 2104-1144010, box-type with pressure regulator and return drain line. The injection is carried out using four parallel-acting injectors. Installation of nozzles BOSCH 0 280 158 502 (black, thin), SIEMENS VAZ 6393 (beige, thick) or other types with appropriate parameters is possible.

The ignition system includes: a model 2112 ignition module mounted on a special bracket on the cylinder block, spark plugs and high voltage wires. The ignition module contains two ignition coils and two electronic controls. In accordance with the control signals from the control unit, the ignition module generates and supplies high-voltage pulses to the spark plugs.

Ignition control is assigned to the electronic engine management system. This system provides control of the amount of air and fuel supplied to the cylinders, controls the operation of the fuel pump, controls the supply of high-voltage pulses from the ignition coil to the spark plugs and adjusts the ignition timing, adjusts the crankshaft speed to Idling... The main control element of the system is the electronic control unit (ECU) -controller.

The engine complies with the EURO-2 toxicity standards.

It seems that, starting back in 1966, together with Fiat, the production of a people's car, even the most unbridled projectors from the Soviet elite did not expect that their undertaking would outlive not only themselves, but also the state that gave birth to it. However, this family of rear-wheel drive cars managed to see the collapse of the Soviet Union, and even the beginning of a new century, deservedly earning the nickname "classic". And now this classic will no longer be: after 28 years serial production The VAZ-2104, the last of the cars designed in Togliatti on the basis of the Fiat-124, has ceased to be produced.

The abandonment of the outdated family took place gradually. In 2006, they stopped assembling the "six", in 2010 - the "five", and in April of this year and its luxury modification, once a dream sedan VAZ-2107. The Quartet lasted only a few months longer.

In an amicable way, they should have abandoned all this ancient brood a long time ago, about fifteen years ago. Indeed, in addition to, let's say, not outstanding by the standards of the new millennium, driving performance, these cars are monstrously unsafe and regularly occupy the last places according to the results of all independent crash tests. But at first it was not up to the smallest detail: the auto industry, along with all the other "blunders" after the collapse of the USSR, was in a deep depression. When he woke up, he discovered that the demand for "Zhiguli" had not gone anywhere: it was inexpensive to buy, and it was handy to repair, and the permanent repair was compensated by its ease. The market is the market, and the management of VAZ decided not to cut the goose that lays the golden eggs. She was simply transplanted to another perch. The assembly of "long-livers", 2104 and 2107, was set up at IzhAvto.

If it were not for the crisis and the accompanying programs of concessional lending and bonus utilization, perhaps, rear-wheel drive "basins" would not have been two years ago. But government subsidies designed to save the domestic manufacturer did their job - the VAZ-2104 was in the top five best-selling Russian cars... Compatriots stocked up on Zhiguli, and the end of anti-crisis programs logically led to a radical drop in demand.

For example, this year the "four" takes only 18th place in the list of the most popular models (according to the results of the first eight months, its sales fell by 71% in relation to the same period last year).

VAZ understood everything and announced the end of the era. Now, finally, the most affordable cars will be cars developed at the turn of the century, if not fresher. The same Togliatti residents together with the alliance Renault nissan ready to flood Russia with relatively modern "Priors" and "Largus". Not to mention the Kalina - the second generation of this car was recently presented to the public with fanfare. There will be at least one airbag (optional up to four) and even - believe it or not - automatic transmission gear!

In general, we survived. Now, even AvtoVAZ products - once a favorite subject of car enthusiasts' jokes - can be looked at even if not without a smile, but at least without shutting their eyes. And for true connoisseurs of vintage cars, who do not have enough stock of the "classics" (in the coming months it will still be on sale), in the coming years a roundabout maneuver will be available - buying a car in Egypt. There they still assemble from car kits the VAZ-2107 dear to the heart, and even with air conditioning. Only 48 thousand Egyptian pounds (about 227 thousand rubles) plus transportation, customs clearance and utilization fee - and you can go down in history as the owner of a truly unique re-export car.

Model history and overview

VAZ 2104 is a deeply modernized five-seater station wagon of a classic layout, produced by the Volzhsky AW tozavod since 1984. VAZ 2104, which belongs to the second generation of the "classics", replaced the station wagon of the "first" generation - VAZ-2102 on the conveyor. But for another year they were released together. At present, VAZ-2104 is produced by IzhMash OJSC (Izhevsk).

VAZ 2104 with a station wagon, made in the same style as the basic AW vehicle of the family - the VAZ-2105 model, is convenient for transporting both passengers and goods. Therefore, the "four" during its existence has deservedly gained a reputation as a family-country car and a delivery van for entrepreneurs engaged in "tent trade". The car is perfect for long journeys and city trips.

The "four" has a roomy interior, the useful volume of the trunk is increased due to the folding rear seat. The tailgate floor-line connector provides convenient handling. These qualities, as well as unpretentiousness in operation, still ensure the popularity of this domestic subcompact passenger-and-freight AW car.

VAZ-2104 at different times had modifications 21041, 21043 and 21043-07, differing in engines of 1.2 liters, 1.5 liters and a "seven" saloon, respectively. In 1994, the VAZ-2104 with a 1.3-liter engine was discontinued. Today, the base model is the VAZ 21043 with a 1.5 liter engine and a five-speed manual gearbox, which makes the VAZ 21043 AW car more dynamic and pleasant to drive. Not so long ago, a modification of the VAZ-21045 appeared with an atmospheric (naturally aspirated) diesel engine produced by Barnaultransmash, with a volume of 1.52 liters.

In general, the design of the VAZ 2104 model, like all classic models, is ascetic. But the interior of the AW car, depending on your desire, may be different. A more economical option involves a standard panel with the minimum required set of switches and instrumentation, upholstery and seats with standard artificial leather head restraints, rubber floor mats. If you want more comfort, then you are offered an improved interior, an original steering wheel and a dashboard with an additional center console, which has an expanded set of function keys and control equipment. The improved interior includes seats upholstered in brushed jersey (front with a high backrest), doors with one-piece moldings, and brushed floor mats. This variant of the "four" will allow you to feel comfortable even on a long trip.

VAZ 2104 and its basic model VAZ 21043 are a car for those who need an inexpensive, but practical and unpretentious domestic station wagon.

Lada with a station wagon are permanent employees of our AW topark. In the early 90s, these were clean fours with 2105 engines, in recent years - forty-third (engine 2103), and now, finally, more comfortable forty-sevenths appeared. The commitment of our transport service to such machines is understandable - for over three thousand dollars, it is difficult to find anything else for the role of a compact and practical magazine delivery truck. And our foursome have to work a lot: almost every trip - with a full load and crawling in Moscow traffic jams.

Another generational change took place last fall - dark green VAZ 21043 and white VAZ 21047 substituted their glossy sides under the Behind the wheel stickers.

Inspection of a new, but painfully familiar car usually leaves a double impression, and in the case of a four, the contrast was especially noticeable. Inhaling the harsh smell of upholstery and fresh anticorrosive intoxicating every AW tomobilist and muttering under his breath: Absolutely new, you cannot get rid of the feeling of some fantastic movement into the past. When you see the engine, you are surprised that this antique looks like it has just been assembled at the factory. Oh yes, it really is just now. A sudden glimpse in memory - and two shots are ideally combined in front of my eyes: the motor of the current four and the one that I once examined in my childhood, climbing onto a stool standing by the car. In a kaleidoscope of memories, for some reason, newcomers flashed, fresh from the store, a Rigonda's radio tape recorder with long legs, a Berezka TV, a Yuryuzan refrigerator.

However, back to 1999. Some changes have appeared in the Zhiguli. For example, instead of long-obsolete cylindrical wiring fuses, there are modern plug-in fuses. True, this is not reflected in the instructions for the car in any way, which will baffle the owners if something shorts out and burns out. Not finding the usual tracks with strips of foil under the cover of the block, they puzzledly try to pick out incomprehensible candies with a screwdriver, sometimes breaking perfectly serviceable neighboring fuses and cursing the useless Operation Manual. Meanwhile, here, on the block, special plastic tweezers are fixed, with which it is very convenient to pull out fuses and relays (see photo). This is precisely why sawtooth notches are provided on the relay housings of the new 90 series.

The break-in period passed without any special surprises - there were only minor problems and, in general, typical for today's Zhiguli: unregulated carburetors junked, especially the EPHH system, battery charging was missing, etc. On both machines, the windscreen washer pumps had to be put in order, which had already failed on the first hundred kilometers. The mesh bottom of the pump is kept in the body only by friction and easily falls out into the tank, after which the pump stops creating pressure. I had to melt the pump bodies with a soldering iron in order to securely seal the bottoms in them.

On the counter, a little over a thousand kilometers - and again the washer of one of the cars fails: the motor buzzes, but idle. It turned out that the plastic tube supplying liquid from the bottom of the tank jumped off the lid fitting, which was made using a simplified technology - without a rim or a Christmas tree. And on the pump of the second car, the tube was barely holding. The soldering iron helped out again - on both pumps, the tubes were securely welded to the fittings, melting the top layer of plastic. The first winter passed without problems - even the rust did not crawl through the paint - it’s too early for her yet. After the second - we'll see.

The VAZ 21047 model has a dashboard and seats from VAZ 2107. A new steering wheel, thick and comfortable, is now being installed on all Zhiguli and cornfields - for some reason, sellers call it a Ford one.

Most VAZ AW vehicles now use plug fuses. To remove them from the sockets of the block, a plastic tweezers in the form of a clothespin are attached. Large tweezers with a ring will help pull the relay out.

ZHIGULI. OPERATING EXPERIENCE

Sergey Kanunnikov

Driving # 9 1998

Exactly two years ago, our publishing house acquired several Zhiguli for economic purposes, among them were two fours: cherry and white. It was a good opportunity to observe both machines for a long time, comparing the durability of the same units and parts. Having worked side by side all this time, two seemingly identical VAZ sheds turned out to be, however, completely different in character. Cherry is always cheerful, smart and executive, white is moody, unkempt, etc. aged unexpectedly quickly.

Let's restore the exact chronology of events. So, on a rainy, dank autumn evening, the fours found themselves in our parking lot. Both are in the basic configuration: zero-fifth salon, leatherette upholstery and engine 1500. They differ only in body color and tires: Yugoslav Trayal is on cherry, and Nizhnekamsk Bl-85 is on white.

After registering with the traffic police, they drove the cars to the first in Moscow, then still an experimental station of instrumental control. Just out of curiosity. The result was discouraging: on the new cars there was an increased backlash in the steering, the brakes were weak, and in the cherry, in addition, the rear axle gearbox was too tight and noisy. We decided to figure out what's what in our technical center Tushino. Dealing with the problems turned out to be easier than a steamed turnip: the backlashes were eliminated by tightening the pendulum arm and adjusting the hub bearings, and on a white car they also extended the fastening of one of the front suspension arms and the ball joint bolts. On the allegedly defective overtightened gearbox, the anther of the drive gear flange was just skewed - it touched the crankcase. Mach was given by experts. One push with a screwdriver - and buy new unit for a thousand (then a million) rubles did not have to. And it still works flawlessly.

The first five thousand kilometers, both cars left without comment, going through only routine maintenance. Everything that is required after running in (changing the oil in the units, broaching the block head bolts, adjusting the chain tension, valve clearances, etc.) was done on time. And on the sixth thousand, the first troubles went. On the cherry four - trifles. Light switch flew reverse- replaced. Minor interruptions in engine operation - rinsed and adjusted the carburetor. At the same time, prophylactically, new Champion candles and Fachet silicone high-voltage wires were installed.

For the White, things immediately went worse. On the sixth thousand, Tosol dripped - the gasket under the flange of the outlet pipe is to blame. I had to drain the liquid and put the pipe on the sealant. Then the clutch suddenly began to engage, and the fork free play adjustment did not help. As it turned out, some of the basket petals lost their elasticity - an obvious marriage, the pressure disc worked with a skew; the clutch did not fully disengage, causing a grinding noise in the transmission when shifting gears. The basket was replaced with an imported one, from the LuK firm - it is still working.

At the eleventh thousand, during TO-2, the cherry car required only consumables (oil, filter), and the white one also requested front brake pads (supplied by Italian, OTA firms) and a new EPHH unit.

Fifteen thousand kilometers: the White Four needed new rubber cushions for the front right shock absorber - for some reason, the relatives were already chewed up.

Twenty thousand kilometers: on the cherry four, we change the reversing light switch again - corrosion has eaten away the plugs.

Twenty-five thousand kilometers: on cherry - the first replacement of the front brake pads; on white - we suffer for a long time with interruptions in the operation of the engine, which do not disappear even after thorough washing of the carburetor. In the end, they indignantly threw out the block of the EPHH system, remembering its creators with an unkind word, and connected the vacuum hose directly to the carburetor - the engine started running like clockwork. Twenty-seven thousand kilometers: The epidemic continues to mow down the reversing light switches. This time we change the frog on the white car.

Thirty-two thousand kilometers: on both fours, problems with starters produced by KZATE are triggered only from the fifth to tenth attempt. On a white car, the replacement of a non-separable retractor relay helped, on a cherry one I had to change the starter assembly to the same 35.3708-01 from Samara. The old one after the repair went into stock.

The next 5,000 kilometers cherry worked without comment, but the white one needed major repairs. Suddenly, there was a lot of noise in the gearbox at idle speed and in all gears except fourth. When the clutch was squeezed out, the noise subsided, which clearly indicated a malfunction of the needle bearing in the connection of the primary and secondary shafts. They removed the gearbox from the car and disassembled it. So it is: on the polished toe of the secondary shaft a piece of the cemented layer has crumbled - a clear defect, the heat treatment technology is broken. It is not surprising that a noise appeared - the bearing needles rumbled, falling into a hole on the surface of the shaft. Having bought a new output shaft, a needle bearing and a little something on the little things, we assembled the box as it should. Now we are firmly convinced that everything is in order in her.

Thirty-six thousand kilometers: an extremely rare and ridiculous malfunction on the cherry car - the gear lever broke along the groove for the damper bushing. They contrived to replace it without removing the box from the car - straight from the passenger compartment through a round hole in the floor tunnel.

But the white one after such a run already began to simply crumble. I had to replace the clutch disc overnight, release bearing, candles, distributor, front brake pads, sound signal, emergency oil pressure sensor, and at the same time put a new mudguard to replace the one lost somewhere on the road. In addition, the car began to noticeably eat up engine oil - between shifts it is necessary to top up up to a liter. Cherry has not yet found such a tendency. By the way, during the last maintenance we used German Liquid-Moli oil of 15W40 viscosity class and American Purolator filters - they have an optimal price-quality ratio.

So, let's summarize. After two years of daily operation, the cherry four feels like new, looks great (not a stain of rust), and the cost of spare parts for it was low: a starter for 400 rubles plus consumables and a little bit of detail. All-season tires Trayal of the T-100 model proved to be excellent - both on rolled snow and on dry asphalt they are in their element. The tread is worn out by about half (a margin of about 5 mm) and absolutely evenly - despite the fact that for 44 thousand km we have never done wheel alignment and balancing!

Her white neighbor on the conveyor belt got a difficult fate - all her life she was haunted by health problems. Once a month, you definitely have to buy something from the spare parts, and even tighten, top up, adjust, clean and lubricate - and even more often. Rust spots are already turning yellow on the light body panels - a repainting of the car is just around the corner. On two of the five Nizhnekamsk tires, several metal cord threads burst, and bald patches immediately formed on the swollen areas of the tread. However, this is not bad for domestic tires - until recently we threw out a BEEL after 20 thousand km.

Why are the two twins so different from each other? They have common genes, as well as the time and place of birth. Is that the white got a birth injury? We will hardly ever know the answer to this intimate question - the impregnable gates of VAZ jealously keep factory secrets.

QUIETER RIDE, SMELLS WITH SOLAR.

Yuri NETHETOV

Driving # 4 2000

Young man on a beige four - this column with diesel fuel... - came a metallic voice under the arches of the gas station. I know I know. I need it here. Putting the pistol into the tank, I go to the window under the interested glances of several Zhigulists.

This is how the test of the diesel VAZ 21045 began - the first cars appeared at the capital's dealers this winter at a price of about $ 4000. With one of them, we went to the training ground, taking as an opponent the usual carburetor four costing, by the way, only $ 2700.

If you do not open the hood, then with this pair it is quite possible to play in Find three differences. The first on the outside is the diesel 1.5 nameplate on the tailgate, the second on the inside is the fuel filter heating button. Moreover, some joker attached it almost to the accelerator pedal itself - I wonder where he saw hands of such length? And there is no indication of the inclusion of heating on the dashboard. The third difference is noticeable only when turned on. almost said ignition, of course, power supply. In this case, the glow plug heating icon lights up for 10-12 seconds. This pause has to be done with each start, regardless of the engine temperature. We could not find any other differences, even the choke handle is in place, however, now it controls the fuel injection advance angle corrector.

Let's take a look under the hood. There is an inscription VAZ-DIESEL on the plastic noise-insulating cover of the power unit, but in its outlines it clearly resembles something painfully familiar, seen hundreds of times in the engine compartments of Zhiguli. You don't have to rub your eyes, they don't lie. The VAZ-341 diesel engine (ZR, 1996, No. 2) is indeed based on a modified cylinder block of a conventional VAZ 2103 gasoline engine. By increasing the piston stroke by 4 mm, its working volume has been increased from the previous 1.45 liters to 1.52 liters. This motor was developed in Togliatti back in 1980-1985, and it is now being produced at Barnaultransmash, albeit in very limited quantities.

What else is unusual about the engine compartment? The hood is pasted over from the inside with soundproofing sheets. There is noise-absorbing material on the bottom, on the metal protection of the crankcase, but this sandwich will most likely not live in such a pernicious place for long - either the foam rubber will rot, or the protection under a wet compress will rust. For a starter with a capacity of 1.7 kW, a battery with a capacity increased to 65 Ah was required.

The opposite corner of the engine compartment was occupied by a hefty fuel filter, the usefulness of which is difficult to doubt, knowing about the quality of domestic diesel fuel. Moreover, there is an expensive Boshevsky high-pressure fuel pump - it's not a sin to take care of it. By the way, the injection pump is driven, like the camshaft, not by a chain, but by a toothed belt. At the very bottom, another unusual unit is hidden - a vacuum pump. Indeed, in a diesel engine, in contrast to a gasoline engine, the pressure in the intake manifold is practically equal to atmospheric pressure. So you have to create a vacuum in the brake booster using a special pump.

To do away with the differences, we note that the diesel car has a main pair 3.9, while the gasoline has 4.1. There are also changes in the suspension - stiffer front springs. These are installed on the right-hand drive export modification, and only on the right.

What does the new engine on the four give? First of all, we note the more confident operation of the diesel engine at low revs. Under the measured boo-boo-boo, he pulls smoothly in fifth gear from 30 km / h without jerks, dips and threats to stall. True, there are no dynamics, and if a small hill turns sour, well, who is crawling up the hill on the fifth? If you go slowly, you can practically forget about the gearbox. You can even get under way in fifth place without touching the accelerator pedal! Of course, this is a clutch abuse, but it demonstrates the character of the diesel very convincingly.

For the sake of objectivity, we tortured the second car in the same way, while discovering one curious thing. In principle, putting up with the sometimes jerky jerks, and a gasoline engine can be driven in a similar way. But my heart is bleeding, and my hand still reaches for the gear lever to tuck in the third, or even the second. But the diesel engine rattling at low revs does not cause any psychological stress in the driver.

If you try to drive dynamically, then you will have to switch, on the contrary, much more often than on the usual four. Nevertheless, the diesel loses the race outright - what can you do, because it has only 54 hp. with. and even with a narrower operating speed range. By the way, there is clearly a lack of a tachometer, which will most likely be noted by a category B owner, who is not used to diesel engines.

The precise instrumentation confirmed the subjective impressions. When accelerating in third gear from 20 to 90 km / h, the diesel initially has a slight advantage, due to better traction at low revs. However, as they grow, the petrol four begins to overtake the diesel one, and then overtakes it, gaining 90 km / h as a result, almost 3 s faster. In classical exercises - acceleration to a hundred and maximum speed - the fight did not work: VAZ 21043 did not allow for a moment to doubt its leadership, being faster, respectively, by 8 s and 13 km / h. Moreover, the same difference in dynamic performance remained on fully loaded vehicles.

AW vehicles also differ in noise level. Diesel is noticeable, 6-8 dB (A), louder at idle. But with an increase in load and speed, this difference first decreases to 1-3 dB (A), and then disappears altogether.

And now we have come to, perhaps, the most important thing, for which, in fact, they buy a diesel AW car - to fuel efficiency... During the test, the cars covered almost 650 km, consuming 7.8 liters of diesel fuel and 8.7 liters of AI-92 per 100 km. As you can see, the difference in liters is small - about 10%. However, taking into account the cost of fuel - on average 4.5 and 6.3 rubles. per liter, we get, respectively, 35.1 and 54.8 rubles. for 100 km. And here the positive balance is much more impressive - 36% or almost 20 rubles. net savings for every hundred kilometers traveled. So the same $ 1300 overpaid for a diesel engine, in the absence of serious repair costs, promises to pay off in 180 thousand km. By the way, about repairs - having asked about this at several branded service stations indicated in the VAZ 21045 service book, we received a short answer: we do not deal with diesel engines.

What is the bottom line? Of course, a 1.5-liter diesel engine is rather weak for a Zhiguli, a volume of 1.8 or even 2.0 liters is needed here. Nevertheless, the VAZ-341 has its merits. And in order to feel them in full, you just need to turn from a sprinter into a stayer and ride calmly, without trying to prove to anyone that you are faster.

LIGHTS WITH DIESEL.

OPERATING EXPERIENCE

Anton CHUIKIN

Driving # 7 2000

The editorial park has the first light diesel engine! Using the example of a four with a VAZ-341 engine, we plan to share our experience of communicating with diesel engines (fortunately, our engine is similar to many foreign ones) and evaluate their advantages and disadvantages against the background of familiar gasoline cars when working in Russian conditions.

For starters, a little economy. Guided by our own recommendations (ZR, 2000, No. 4), we went for the rare diesel Zhiguli in Togliatti. And they paid off - the difference between Moscow and local prices (about 10 thousand rubles) more than paid for the trip.

At the end of April, VAZ 21045 cost 110 thousand rubles on the banks of the Volga; carburetor station wagon VAZ 21043 - about 85 thousand. To calculate when the diesel will pay off, we wrote down two prices at each gas station - from the graph for diesel fuel and AI-91. Our AW car consumes on average 6.6 l / 100 km; a gasoline analogue, which almost simultaneously got into the editorial office, under the same conditions - 9.5 l / 100 km. So far, the diesel saves 320 rubles for every thousand kilometers, which means that by 80 thousand, God willing, the total operating costs of VAZ 21043 and 21045 will be equal. Perhaps this will happen even earlier, because it is somewhat cheaper to maintain a diesel AW car - for example, it is enough to adjust the valves every 30 (not 10) thousand kilometers.

We will return to scheduled maintenance, but for now - first impressions. Let's supplement the test of two fours, diesel and carburetor (ZR, 2000, No. 4), with two remarks about fuel. A pleasant thing: the appetite of our diesel engine turned out to be noticeably less than that of a non-driven car. Never before had it been so rare and cheap to refuel on a thousand-kilometer journey from Tolyatti - we used up only 60 liters! Unpleasant: the dispensers at the gas station, where the drivers of diesel cars are forced to drive up, not only are the most unkempt, they are also often equipped with a pistol of a really huge diameter. And in an ordinary quadruple tank, the neck is closed by a third.

Now about TO-1, which is used to scare the owners of rare models. Until the service station personnel are trained to work with the VAZ-341 engine, the plant's subsidiary that produces VAZ 21045, ZAO SPAR, is forced to send flying teams for warranty repairs. True, there were only a few such cases. And in the near future the diesel engine will be officially taken under the wing of the plant's service network.

However, not everyone is afraid of the unknown - the Moscow service station Gagarin-Lada (mentioned in the service book) immediately agreed to carry out the first maintenance of the first VAZ 21045 for itself. transmission oil after checking and stretching the chassis and lubricating the doors, the mechanics made an attempt to eliminate themselves: they say, no one will do anything to you with a diesel engine, so go to the collapse and. all (this is for 950 rubles; wheel alignment angles - about 400 rubles more!). I had to show the service book and the VAZ 21045 Maintenance and Repair Technology, which by the way came across in Togliatti. According to the books, it turned out that at least one could not get out of adjusting the station valves - especially since the gas distribution mechanism is identical to the VAZ 2108. We advise all owners of diesel fours to follow our example - set the clearances within the power of any service station! The mechanic, however, had to sharpen the open-end wrench in order to wring out the pushers and remove the washers (the eight-piece device does not fit because of the different shape of the block head). However, it will really be useful to him only in the future - all thermal gaps were normal, which was a pleasant surprise.

Since we, like many AW enthusiasts, are more important to the stamp in the maintenance coupon (just in case of a warranty case) than to the actual routine maintenance, on this we said goodbye to the service. The wheel alignment angles in 15 minutes and half the price were adjusted in the workshop next door; and such a trifle as the headlights (the Gagarin people seem to have forgotten about them), we directed in the right direction on our own.

Of course, it would still be necessary to check and adjust the injection pump - for toxicity. But so far there are no complaints, we decided to postpone it. and if necessary, we will look for specialists in foreign light diesel engines - by the way, there are enough proposals. The nearest large-scale routine maintenance - at 30 thousand: replacing the toothed belt and setting the fuel injection advance angle. Then, we hope, there will be a reason to rejoice for the service network.

So far, the impressions of the diesel engine are favorable. Returning to the comparison with the carburetor counterpart, I will sum up: yes, the diesel loses outright in terms of objective indicators - power, dynamics. But if we evaluate the subjective, that is, the driver's sensations, the situation changes noticeably - the confident diesel traction disposes to itself!

The running-in of VAZ 21045 is completed. Ahead - check at the range, runs, tests. Then let's talk in more detail.

Externally, the diesel four is distinguished by a nameplate and an exhaust pipe wrapped in a pig's tail - so that soot does not pollute the right lamp.

In order not to harm the high pressure fuel pump, it is necessary to drain the water (sludge) from the fuel filter every 1-2 thousand kilometers, and then pump the system.

At gas stations in the capital, refueling nozzles, as a rule, are thin, and this detail in the neck - a gasoline inheritance - does not interfere. And on the tracks it is better to try on the speakers in advance. or break the hindrance by solving the problem once and for all.

VAZ 21045: DIESEL FOUR

Maxim Sachkov

Driving # 11 2003

It was the first light diesel in our AW topark. Like any firstborn, he caused a lot of trouble. But today, while preparing the final report on the operation of VAZ 21045, we feel a slight sadness - an eggplant station wagon no longer rumbles under the windows of the editorial office, notifying colleagues: Sachkov has gone home! The firstborn is not only worries, but also joys.

In September, it hit 120 thousand: only 5000 km remained to the resource declared by the manufacturer. So, it's time to get ready for Barnaul, the homeland of the VAZ-341 engine, in order to subject it to a complete revision. Expensive, just pick up the missing mileage.

Four days - and here we are four thousand kilometers from home. The four are familiar with the road to the Altai Territory. In her youth, she was the first editorial machine to blaze a trail east. Prudently not competing with the hurrying dozens, they overcame the European part, smoked the Ural sky (on long climbs, the engine sour without a full supply of fuel), and in the Siberian expanses they took the lead (our 100-110 km / h is enough - here it is somehow not customary to reckless ).

True, this time the path turned out to be a little longer - an extra hundred kilometers to detour the repaired Togliatti dam across the Volga. It was easier for a diesel engine to run on the beaten track - the overall average speed, excluding lunch breaks, was 85.9 km / h, which is almost 5 km / h higher than the result of three years ago. And this with an almost unchanged appetite - fuel consumption from Moscow to Barnaul was 7.2 l / 100 km. It turns out that for more than a hundred thousand, the motor has not lost its strength. However, this is a subjective assessment, and we will obtain objective characteristics at the plant.

At this very stand, the newly assembled engine was driven at the beginning of 2000 - then Barnaultransmash produced the first thousand VAZ-341 diesel engines. The plant stores the data of pets: we are raising case number 897, this is the number of our engine. The power that he showed in infancy is 36.5 kW. Today? The resource mileage, of course, was not in vain - the motor produced 34.3 kW. However, this is only 6% less than the initial value - not bad at all! The measurement results are shown in the table, and it's time for us to start the operation, which both engineers and doctors call the same. A few hours - and the engine is decomposed to the bone.

Inspection with passion began with the main part - the cylinder block. Recall that the block, pistons and rings did not leave the entire period. At the 35th thousand, the ring broke a groove in the piston and rubbed a hole in the cylinder (about the reason - below); the failed parts were changed under warranty. The second block was more fortunate - traces of hone are perfectly visible on the cylinder walls. Considering that the honing depth is on average 5 microns, and the block is sent for repair with wear of 0.15 mm (75 microns in radius), this part is destined to have a very long life. If, of course, everything goes well with the pistons.

The diesel piston experiences much greater stress than the gasoline piston. The area around the groove of the first compression ring needs strengthening. On the pistons of the VAZ-341, it is remelted: additives are introduced with an electron beam, which increase the resistance to stress. The first set of pistons turned out to be defective, the groove and the remelting zone did not coincide - this is the reason for the overhaul at the 35th thousand. Alas, we were not alone in this failure.

Then the plant carried out a warranty repair of the motor. The new pistons, having served 90 thousand, remained in good condition, although on one of the grooves they worn out somewhat - the gap between the wall and the ring is 0.35 mm, with an allowable 0.3 mm. Experts suggested that the piston would be enough for another 50 thousand, that is, the declared resource of the piston group will work out. Imported Schottle rings passed the revision without any comments.

By the way, after that incident, the plant improved the piston manufacturing technology by increasing the penetration depth. And today in Barnaul completely new pistons are being tested: in the area of the first ring they have a reinforcing insert, which minimizes the risk of marriage. In addition, there are developments in a different form of the piston: the designers promise to reduce oil consumption to the level of gasoline engines.

Our diesel asked for about 0.3 liters engine oil for 1000 km; VAZ allows 0.6 liters, although in practice this consumption looks excessive. A manifestation of diesel appetite is the release of oil into the air filter through the crankcase ventilation hose: with us, at an admissible consumption, the paper element has already taken oil baths after 5 thousand. We are glad to announce that the plant has cured this childhood diesel disease too - the hose was taken out behind the filter. This, of course, does not reduce the consumption, but at least the element does not suffer, and the owner is not afraid of a puddle of oil in the pan.

The crankshaft, liners, persistent half rings honestly served all 125 thousand. Moreover, the dimensions of the parts still fit into the drawing tolerances, so they can be safely sent to the assembly site for new engines. The same applies to the camshaft and tappets.

Alas, such a pleasant picture was spoiled by the cylinder head (cylinder head): the guide bushings were worn out, the gaps between them and the valves were up to 0.2 mm in the lower part. The repair manual allows you to tolerate up to 0.3 mm, so we still had a margin - the question is, what?

Perhaps, the poor condition of the bushings is also our fault: we arrived in Barnaul with no thermal gaps, the valves were pinched. Accustomed to the fact that a diesel engine with its direct valve drive a la Samara only occasionally requires adjustment, we carried it out at the beginning of operation, then on the 35th and 70th thousand, etc. relaxed, especially since more than one or two washers did not have to be changed.

Another weak point in the diesel engine there was a gasket between the head and the block. Shortly before disassembly, the engine began to overheat, and in expansion tank bubbles appeared. The leakage of the gas joint was diagnosed correctly - after replacing the gasket, everything returned to normal. Note that its breakdown is not an isolated case, but another childhood disease VAZ-341. The fact is that the diesel engine needs its own cylinder head bolts, with a large tightening force. Until some time, they were unified with gasoline engines of front-wheel drive models: sometimes there was not enough effort and the gaskets began to miss. On current motors, the block and the head are pulled together by special diesel bolts - they can be distinguished by a special head.

An oil pump that has properly worked its full resource can easily be confused with a new one. And a small backlash appeared in the bearing of the cooling system pump - it is better to replace it so as not to tempt fate. True, not every Zhiguli pump (a unit for a diesel engine differs only in a large impeller diameter) nurses the required resource.

Bosch fuel equipment, contrary to the assurances of skeptics (the delicate plunger pair will be destroyed by the Russian solar oil, delicate adjustments will fall under the heel of the Russian service), worked 125 thousand perfectly. The audit on the 100th thousand, carried out by the masters of the corporate service, confirmed this. They only preventively replaced the rollers of the high pressure fuel pump (high pressure fuel pump).

It is best to apply the principle to injectors and high-pressure fuel pumps: do not interfere with the machine! Judge for yourself: in one very eminent institute, we were offered to pay 250 dollars for replacing the nozzles of all nozzles and adjusting the injection pump - they say, it is already poking around. It was a hundred thousand kilometers ago, but the equipment is still working. Once they tried to adjust the opacity on the stand - as a result, the motor stopped pulling. Still - all his strength went to push monstrous portions of soot through the muffler.

We arrived in Barnaul with an incorrectly adjusted fuel injection advance angle and overtightened injectors - another result of incorrect work of servicemen.

Of course, sometimes it is useful to tighten the nuts and screws of the injection pump - for example, we had to increase the idle speed in hot weather, otherwise the engine would stop when the gas was suddenly released. We talked about how to adjust the smoke level strictly by eye. How to replace a nozzle - too, the work is not difficult. But in general, once adjusted equipment does not need your intervention. Even a light tapping of the injector is not a cause for concern - it will go away by itself when you treat the car with good fuel.

As for the bad diesel engine: in three and a half years, we only ran into frankly bad fuel twice, when the engine stopped pulling and started up unimportantly. The cost of one poisoning was the nozzle - we replaced it right on the Chelyabinsk street, and the removed one was subsequently sorted out (sorry, right in the basement of the editorial office) and since then we have taken it with us as a spare part. There is nothing special to say about attachments - the generator is the same as on the gasoline classics, and behaved predictably. The original unit - a vacuum pump - worked its entire life without any remarks.

Diesel modification of any AW car is more expensive than gasoline. But thanks to the lower fuel consumption, the difference can be recouped. How fast? We constantly monitored the prices of gasoline and diesel fuel, calculated the average consumption - ours and its analogues, VAZ 21043 from the editorial AW of the farm. The diesel four went to zero with a mileage of 76 thousand km. By the 125th thousand, she brought, so to speak, net profit of more than 16 thousand rubles. Even if the benefit is small, but this is absolutely real money that remained in your pocket! By the way, today, when the difference in the price of gasoline and diesel fuel has grown to 2 rubles, the forty-fifth pays off twice as fast!

You did not take into account, the meticulous reader will say, the extra liters of expensive oil consumed by the diesel engine. In response, you can recall the less laboriousness of TO (down with the ignition adjustment, gaps in the spark plugs, even valves every 10 thousand). However, there is exact data - here is a graph of operating costs for VAZ 21045 (see fig.). Without taking into account diesel fuel, each kilometer cost us 41 kopecks - not bad at all for any Zhiguli with such a mileage! In general, the diesel engine actually turned out to be low-budget, confirming its reputation. For this, diesel engines are appreciated all over the world; We hope they will try it with us.

The diesel has done its job, the diesel can go away: the AW vehicle has exhausted its resource and has been decommissioned from the AW topark ZR. Results on this long test he showed not outstanding, not excellent - on the whole, just not bad. But for some reason it is a pity that 125 thousand and three and a half years are already behind.

PROS AND CONS OF THE DIESEL FOUR

The main advantage is efficiency, but you have to pay worse dynamics than a gasoline AW car. On the other hand, the motor is much more comfortable on the go, especially if you study its character. For example, traction is smoother, no suction is needed. By the way, thanks to the favorable torque characteristics on the diesel four, it is easier and safer to drive on winter roads (noted by ZR experts). Alas, in winter you may face problems with starting - below minus 20 AW, the car was reluctant to start. Diesel makes more noise at idle, but at speed you can hardly distinguish its hum from its gasoline counterpart. Another argument for is not so appreciated in Russia: the diesel four has fulfilled the Euro II standards.

Is the motor not very reliable? Alas, it was, but the manufacturer has cured childhood illnesses and is modernizing the design. Unfortunately, the service is completely unprepared to service and repair a diesel engine - the simplicity and maintainability of the design, the reliability of imported fuel equipment can serve as a consolation.

Diesel fours are now in short supply. They will be produced by Izhmash - a program of up to 5 thousand cars per year is planned. However, this shortcoming of VAZ 21045 - a small circulation - today it is easy to fix the consumers themselves, creating demand.

HOW TREATED CHILDREN'S DISEASES OF THE VAZ-341 DIESEL:

a - on some of the first motors, persistent half rings quickly wore out. The crankshaft received freedom in the longitudinal direction. The construction with four half rings helped to remove the problem;

b - dark area around the groove of the first ring - hardening remelting. Here its section is small, the groove will be broken. On current pistons, the remelting zone is increased - shown by a dotted line;

c - special diesel cylinder head bolts (on the right) with a high yield point increased the reliability of the gas joint. They pull the head closer to the block. Perhaps the gasket will be changed on future motors;

d - oil got into the air filter through the ventilation hose. After modernization, it bypasses the pan, entering directly into the intake manifold.

CORROSION MAKES A POINT

Maxim Sachkov

Driving No. 1 2004

Recall that when the diesel four was registered in the editorial office, we decided to use the example of the Zhiguli to check what the additional anticorrosive gives and how much factory protection is enough. The car was treated with Tektil exactly half, wheel arches were installed only in two wheel arches. The body was inspected annually and the condition of the parts was assessed on a five-point scale.

Three and a half years behind, the tests of VAZ 21045 have been completed (engine report - ЗР, 2003, No. 11) - the time has come for the final report. The right side, treated with Tektil and protected by wheel arch liners, having survived three Moscow winters, has survived, on the whole, not badly. The assessments received by the body parts in July (see ZR, 2003, No. 7) remained the same: the average score was 3.9 (maximum - 5 points). Only in the doorway there was a little more yellowness. Alas, even the additional anticorrosive could not protect the parts. But the changes are not so significant as to reduce the marks by a point - a small minus is enough. The same with the tailgate - a favorite place for corrosion. However, even here, in the machined half of the part, there is still a long way to go through holes.

The left side, protected only by the factory anticorrosive material, has also remained almost unchanged for several months (in July it was set to 2.7), with the exception of the front wing. Rust, actively devouring the metal from the side of the wheel housing, made its way out. The day before the sale, the first hole appeared near the headlight. Obviously, by the spring, the wing will resemble a colander and will need to be replaced. After him will come the turn of the tailgate - the metal in the corners, where there was no additional anticorrosive, is already loose.

So, here is the result of our experiment: it is not worth saving on additional protection against corrosion. For three or four years of operation, Zhiguli, who have seen only the factory anticorrosive, but they have eaten enough salt on Moscow roads, rot to holes. Competent handling and fenders pretty much slow down the process. In general, we didn’t say anything new, but it’s better to see it once. on someone else's car.

In the capital, Zhiguli without additional anticorrosive rot rot to holes in 3-4 years. The most revealing result of the experiment is a hole in an untreated wing after 3.5 years of operation. The front left fender will have to be changed in the spring. The right one, additionally treated with anticorrosive and protected by wheel arch liners, was practically not touched by corrosion.

VAZ 2104 is a classic 5-door, 5-seater station wagon produced by the Volga Automobile Plant. It is worth noting that in addition to the Vase, the "four" was produced at IzhAvto (2002-2012), as well as in Syzran, Kremenchug, Lutsk and even in Egypt. In total, the model was produced from 1984 to 2012. Its appearance was caused by the obsolescence of the "two" design (by the way, it was produced in parallel from 2104 to 1985). Since a station wagon based on the luxury "troika" did not exist, it was decided to produce it on the basis of an already produced one (yes, model 2105 appeared earlier than 2104 - this is a normal practice at VAZ).

The appearance of the updated classics is completely different from its predecessors. The very first, striking difference is the straight chopped shapes, instead of the usual rounded ones. The second is the absence of chrome-plated parts, they were replaced by plastic ones. "Muzzle" completely from the sedan 2105 - front headlights with combined turn signals, side repeaters are also rectangular. The rear lights were lights from 2105 rotated 90 degrees. It retained the payload of the station wagon of 2102 - 955 kg. Along with this, he retained the main drawback of this cargo platform - protruding "glasses" rear suspension. Fuel tank- as in 2102, on the left. The roofs of classic station wagons had 2 parallel punching, which served as amplifiers.

Interior

The interior has also been completely redesigned from the previous station wagon. The salon was installed from 2105 - new door cards, seats, dashboard. The luggage space was now separated not only by the back of the rear seat - now a shelf was installed there, similar to hatchbacks,.

| Type of | Volume | Power | Torque | Overclocking | Maximum speed | Number of cylinders |

|---|---|---|---|---|---|---|

| Petrol | 1.5 l | 53 h.p. | 96 H * m | 23 sec. | 125 km / h | 4 |

| Petrol | 1.2 l | 58 h.p. | 84 H * m | 18 sec. | 140 km / h | 4 |

| Petrol | 1.3 l | 64 h.p. | 92 H * m | 18 sec. | 137 km / h | 4 |

| Petrol | 1.5 l | 71 h.p. | 104 H * m | 17 sec. | 143 km / h | 4 |

| Petrol | 1.6 l | 74 h.p. | 116 H * m | 17 sec. | 145 km / h | 4 |

A lot of power units were installed on the car. At the beginning of production, motors familiar to many were installed: "three-wheel", 1.5 liter, 77 hp. and, new at that time, a VAZ 2105 rotary engine with a volume of 1.3 liters. Later versions were equipped with VAZ 21067 and 21073 injection engines, 1.6 and 1.7 liters, and even a VAZ diesel engine. Aggregated together with the classic 4-speed "", and later versions of the 5-speed. It is interesting that a "sedan" main pair 3.9, or different from 2102, 4.1, was installed on the car.

Suspension

Suspension inherited from its predecessor - reinforced classic. Namely, the front independent, on levers with springs, and the dependent rear, also spring-loaded.

Since it was later removed from production, today many cars have survived in excellent condition. Although, we must admit that the quality of the latest cars is much worse than the cars of that era. VAZ 2104 was exported under the name Lada Riva. There were also right-hand drive versions. Export vehicles were fitted with a speedometer graduated in miles. "Four" has become, perhaps, the most popular domestic station wagon. It is actively used in the "Russian Post", having a corresponding color and a white-moon lighthouse on the roof.

The layout of the station wagon has always enjoyed increased interest among domestic motorists. The opportunity to transport all the mother-in-law seedlings with the mother-in-law in the cabin, and not on the top trunk, was considered a serious value. The seedlings transported on the roof waved bushes along the road and got lost on bumps, while in the cabin everything arrived entirely.

Place in the lineup

In the silhouette of the popular station wagon VAZ 2104, the contours of its prototypes are easy to read - domestic VAZ 2102 and the Italian Fiat 124 Familiare. The contours are modest and laconic, yet stylish and modern. It is not for nothing that the "four" has grown so tightly into the market. In 1984 - 2012, it rolled off the assembly lines of seven companies, including AvtoVAZ and IzhAvto. The "four" ousted its domestic predecessor from production in a year, and survived the Italian for two decades.

Having conceived to update the model of the first generation rear-wheel drive station wagon, the designers of AvtoVAZ did not look for good from good. The body of the popular VAZ 2105 sedan was made two-volume, supplementing it with details from the VAZ 2102. The model was 2104. The model looked fresh, retained all the functional advantages of its predecessors, such as a low loading height and the absence of a tailgate in the luggage compartment.

The only objection that the market raised was about engine power. Riding with a large cargo compartment filled to capacity required a more powerful power unit. "Fours" were often used for cargo and passenger transportation, including off-road, and the issue of engine power was very relevant.

The answer to this market challenge was the VAZ 21043 model. This time, the designers were not particularly smart either. The station wagon was equipped with a more powerful, well-proven from the point of view of the possibility of repairing it, an engine such as a VAZ 2103 carburetor with a working volume of 1.5 liters.

The car turned out to be a feast for the eyes. Optimal in terms of the “functionality / comfort” ratio, it allowed the spouse to be taken to the general store and feed to the farm. Balanced in terms of power / efficiency ratio, the car confidently accelerated and maneuvered with full load.

Station wagon engine

The engine carburetor VAZ 21043 is older than the engine of its prototype 2105. It so happened that the modified "four" became really popular with an outdated power unit... By the time it was installed on the VAZ 2104, the 2103 engine had been making for more than 10 years, and on the 21043 model it lasted almost twenty more. In total - a record three decades on the assembly line.

The carburetor VAZ 21043 is not the result of the modernization or tuning of the 2104 engine. Its device is a return to the old ideas, well tested on the 2103 model. The 2104 engine has a more modern timing belt drive, but the engine with a chain mechanism in 21043 will last for almost ten years outlived his descendant.

The power unit has a working volume of 1452 cubic meters. cm. The piston stroke is 80 mm, and the five-cylinder motor is 66 mm with the same cylinder diameter of 76 mm. Such a geometric difference gives a great return in 21043. This engine develops a power of 71.4 liters. with. at 64 hp with. at the five unit.

In terms of torque, the 2103 long-stroke engine performs well at low to medium revs. The 2105 short-stroke motor gains an advantage when the tachometer needle goes beyond 4,000 rpm. For a semi-cargo station wagon, this advantage was not decisive, and even with less noise and increased maintainability of the timing drive, the five motor yielded the market to a more powerful three motor. An additional argument is the repair of the VAZ 2103, including the adjustment with your own hands, does not cause difficulties. VAZ 21043 became the most massive station wagon of AvtoVAZ in its history.

Technical characteristics of the car

The most noticeable changes in the VAZ 21043 have undergone the characteristics associated with the replacement of the engine, as evidenced by the operation manual:

- by 2 km / h, up to 145 km / h, the speed increased;

- fuel consumption has increased slightly: in the urban cycle, 2104 spends 9.9 liters of AI-92 gasoline per 100 km, and 21043 - 10.2 liters of fuel of the same brand;

- acceleration to 100 km / h has hardly changed.

Outwardly, the 4th and 43rd modifications are practically indistinguishable. A heating device and a wiper on the rear door glass have appeared, but the specialist will reasonably object that the 2104 models have long been equipped with these options in the export configuration.

Often on the roads there is a car that differs from 21043 with a "seven" interior or front end of the radiator. It happens that another dashboard is installed. Among the people, this car was named VAZ 21047, which is incorrect. Index 21047 means a modification with a right-hand drive, intended for export. A station wagon with a cabin from the "Seerka" has the designation VAZ 21043-20.

Development of the idea of station wagons at AvtoVAZ

Having launched the VAZ-2104 into series in 1984, the designers of AvtoVAZ did not remove whatman paper from the drawers. They continued to develop the idea of a station wagon, developed variations of the flagship modification of the VAZ 21043. During the years of production of the 43rd model, they were tested:

- 21048 - diesel VAZ-343, 1.77 liters;

- 21041i - 1.6-liter VAZ-21067 injection engine;

- 21041 VF - injection VAZ-2103 1.5 liters.

These modifications were not mass-produced, but all these years they supported domestic designers in a relative form.

Having exhausted the potential of the body in twenty years of release, and in thirty years - the potential of the motor, modification 21043 left the production line. But the objective advantages of station wagons have not gone anywhere. New groups of layout advocates have emerged. These are townspeople with large families and young people who appreciate the ability to transport large-sized sports equipment.

The generalists are strengthening their positions in the market. And AvtoVAZ is in the lead in this. Recently, the Lada Largus station wagon has become popular. This car, like the VAZ 2104 at one time, has a European prototype - the Dacia Logan MCV model produced by Renaul-Nissan. Lada Largus is available in both 5-seater and 7-seater versions, which expands its capabilities. Largus engines tested on Renault logan and have excellent specifications... The spare wheel under the bottom reduces ground clearance, but the promising Lada Largus Cross is devoid of this drawback.

Domestic heirs of the legendary station wagon VAZ 21043 are still leading in our market, now competing not only with the two-box Moskvich-2141, but also with station wagons Kia ceed and Ford Focus.